by Florence Ollivry

Specialized craftsmen

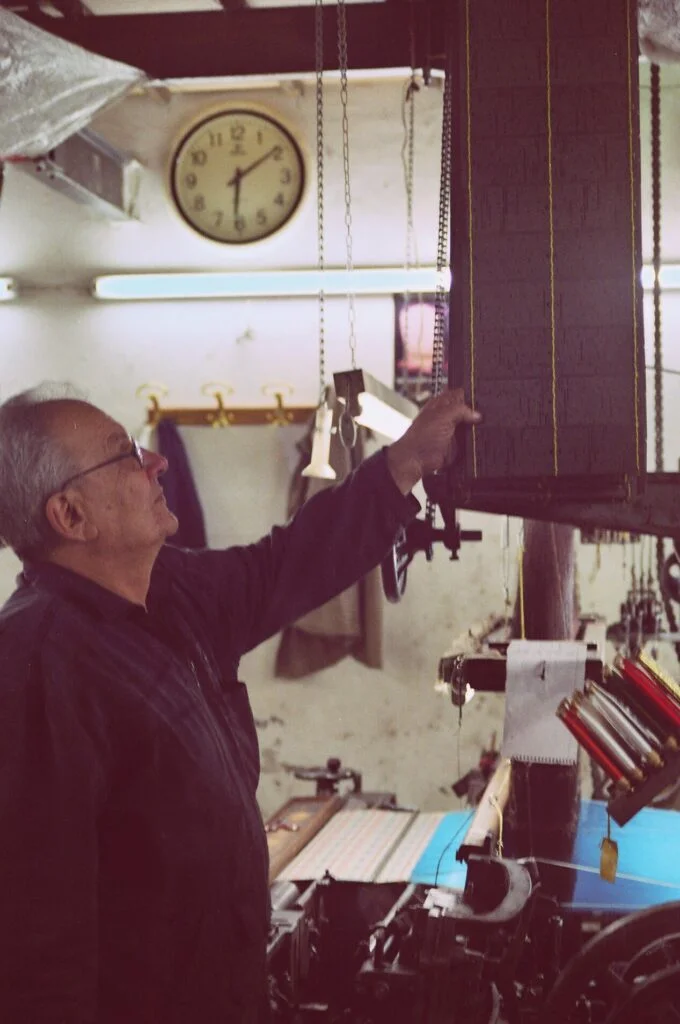

“Someone who sells tarbushes does not sell tassels”, goes the proverb. In Damascus, the textile industry is distinguished by an extreme specialization of professions. Hence the way the silk thread can be woven is complex and consists of many separate stages.After the thread has been wound, it is typically sent to a craftsman in Aleppo who specializes in twisting and doubling silk threads (barim). Afterwards the new, reinforced thread returns to Damascus. It is then taken to Abu al-ʿIzz workshop in Ghouṭa. This dyer is the only one among his colleagues who specializes in dyeing brocade threads. The yarn is given several baths: scouring, dyeing, finishing. . . Back at the factory, it is wound onto bobbins (bakara) or reels (masura). The warp is prepared on the large warping machine (msaddaya). Subsequently the warp is wound on the beam, which is located at the back of the loom. The warp setters (msaddi or milqi) or twisters (mubariz) install the warp.

Integrating modernity without renouncing oneself

Up until the beginning of the 20th century, the organization of work was the responsibility of the trade guilds. Each one was governed by a code or custom (dustur). It consisted of welcoming rites and was relatively closed to outsiders; passing-on the trade was often a hereditary affair. This form of organization limited competition within the profession and thereby tended to discourage innovation and encourage the stagnation of techniques. The fact that all craftspeople of the same trade lived side-by-side in the same district promoted a sense of solidarity but not a sense of competition. For centuries, therefore, there was a remarkable stability in the methods of production.

From the end of the 18th century onward, as Europe was becoming more and more industrialized, the Syrian market was flooded with European silk, and was shaken by it. The powerful trade and finance organization of the Lyon merchants promoted “Europe-style” spinning and discouraged the production of “Arab-style” spun silk. This European economic and cultural penetration resulted in the partial abandonment of traditional flowing garments and hence also of certain fabrics.

Yet, as shown in the Dictionary of Damascene Trade, compiled by the Al-Qasimi family, the local society opposed the outside pressure: the invasion of new techniques, their social framework, their laws, and their culture. However, it also appropriated elements of modernity which might enrich it without affecting its core organization.

With its demand for “Arab-spun silk”, Syria’s handicraft preserved the existence of ancient spinning techniques. Syrian requirements for the raw material, silk worm cocoons, diverted them out of the wholesale circuit, thus hampering the spread of “Europe-style” spinning. The powerful cultural and need-based community that united craftsmen and buyers retained the testimony of a strong cultural identity. In 1947 there were still 6,000 handlooms in Aleppo compared to a mere 1,500 mechanical looms. Despite the introduction of technical innovations, the methods and means of production tended to remain traditional.

For Dominique Chevallier, “economic innovation that comes from abroad but is implanted in a clearly defined human and cultural context has, in return, considerably strengthened this context, which at first appeared to be shaken. New foundations, changes that are certainly impossible to avoid, but for a humanity that has not understood, that has accepted its future creation only in a chain reaction to its past creation . . .” (Chevallier 1982, p. 157).

Ties made of silk

Today, no workers have any memories of corporate initiation ceremonies but we still find the constancy of basic principles which link different craftsmen of the same trade with one another (ḥirfa). To this day these companions regard each other as genuine brothers, and the muʿallim (master of art) is respected just like a father. Apprenticeship occasionally begins at the end of childhood. During the first three years the novice learns the secrets of the trade and receives only a modest wage. His earnings will gradually increase and be five times higher at the end of his career.

Everyone’s speciality is part of a common whole. Silk craftsmen work together to weave the same fabric. The sum total of their labour, their work, finds its outcome where warp and weft meet. The silk fabric is the image of the social ties, the social fabric.

Silk has also imprinted its name on these textile people. The memory of a distant paternal ancestor’s craft, of someone who used to work in the textile industry, is still recognizable in many family names today. Since one-third of trades and shops in 18th-century Damascus were connected to the textile trade, to this day we still frequently encounter “textile” family names – an indication of how important this occupation was:

- Al- Mulqi (the person who passes the warp through the heddles)

- Al-Msaddi (warp setter)

- Al-Fattal (winder)

- Al-Ghaṭṭas (the person who rinses the filaments)

- Al-Ḥallaj (cotton carder)

- Al-Khayyat (tailor)

- Ash-Shashati (gauze merchant)

- Al-Mashshat (fabric carder)

- Al-Makkukji (shuttle maker)

- Al-Hayik (weaver)

- As-Saqqal (the person who puts the silk through strong rollers to make it shine / verb: to calander)

- At-Ṭayyar (lathe manufacturer)

- Al-ʿAqqad (trimmings-maker)

- Al-Ghazzal (spinner)

- Al-Alajati (alaja vendor)

- Ash-Shammaʿ (oilcloth manufacturer)

- Al-ʿAbaji (abaya manufacturer)

- Al-Qaṭṭan (cotton vendor)

- Al-Lababidi (felt maker)

- Al-Qazzi (silkworm breeder)

- At-Tabbaʿ (stamper)

- As-Ṣabbagh (dyer)

- Al-Kabbaba (silk reeler)

- An-Nuwaylati (handloom weaver)

- Al-Ḥariri (silk merchant).

Featured Image: A warper (al-msaddi) is installing the warp threads on the mechanical loom | Florence Ollivry (CC-BY-NC-SA)

Published by Florence Ollivry: In Syria, Florence Ollivry was interested in the history of food and sericulture. She holds a doctorate in religious sciences (University of Montreal; EPHE-PSL) and her research currently focuses on the mystical dimension of Islam.