by Rami Al-Afandi and Hiba Bizreh

Although Aleppo’s traditional soap lacks external beauty, its special charm embodied in its smell and colour inspires your imagination, heart and memory from anywhere in the world to the Suq al-ʿAttarin (herbs market), located in the middle of the big bazaar of Aleppo city. Its fragrance may also take your memory on a trip to the old baths of Aleppo, enchanting you with the scent of laurel.

This laurel soap, in its simple cubic shape, produced over many centuries, has made Aleppo famous. This traditional craftsmanship was one of the most important industries in the city of Aleppo. Nowhere else in Syria was there so much laurel soap produced as here. Some of the Aleppo families were famous for making soap in the soap factories, which were housed in historic old buildings. Though the production was done in the local factories, the ingredients came from different regions of Syria.

The olive oil, its main ingredient, comes from the regions north and west of Aleppo. The laurel oil, which gives the soap its fragrance, comes from the coastal mountains, specifically from the area between Antioch and Kasab. The alkaline substance, essential for the soap’s production, is obtained from the charring of the anabasis plant from the Syrian Badiya (steppe).

Despite the large production of Aleppine soap, its fabrication depends on the season of the olive harvest. As a rule, the production period or soap boiling is from November to March or April.

At the beginning of the Middle Ages, the first soap factories were established in Aleppo, particularly in the Bab Qinnasrin quarter. The business was then moved to the northwest and southwest areas of the Bahsita quarter, where olive oil was delivered through the Jinan Gate. On al-Masaben-Street, which leads from the Jinan Gate to the Citadel, there were more than 20 factories. To the north, the soap road led to the Hayy al-Masaben soap manufacturing quarter, which was demolished in 1975.

In the 16th and 17th centuries respectively, Aleppo experienced an important development in soap making: small factories were replaced by large ones, which were able to guarantee a larger production volume. Most of these buildings were not built specifically for the production of soap, but were still used by soap manufacturers as soap factories. The ground floor and upper floor of the buildings were rebuilt according to production needs.

These changes to the buildings make it difficult to identify special plans of the soap factories or to recognize their age at all. Nevertheless, there are some soap factories known to have existed since the 19th century.

The Zanabili soap factory, outside the Bab an-Nasr, and the Jubayli soap factory, in the Bab an-Nasr quarter, are among the oldest factories in Aleppo, are even dating back to the middle or end of the 18th century.

Despite the great importance of the traditional soap factories in Aleppo, their number in the old part of the city declined sharply during the 20th century, with a mere six soap factories spread over two areas. The first area is Bab Qinnasrin, where the Sabouni and aj-Jubayli factories are located. The second area is Bab an-Nasr, where the two soap factories Zanabili and another factory of the Jubayli family are located, right next to the ar-Ridaiya school (Ottoman school). Another soap factory of the Zanabili family is located directly in front of Bab an-Nasr. The Muqayyiad family owns a soap factory northwest of the Citadel. Finally, the Fansa soap factory, later used for a different purpose, is located in Khan al-Qadi.

The traditional laurel soap factories were not limited to the use of old buildings. Later, many soap manufacturers of Aleppo built modern facilities that spread throughout the city. With the expansion of the soap factories, new families dedicated themselves to soap making, including the Salalahia, Hammami, Abaji, Abu Dan, Fatal and Khayata families.

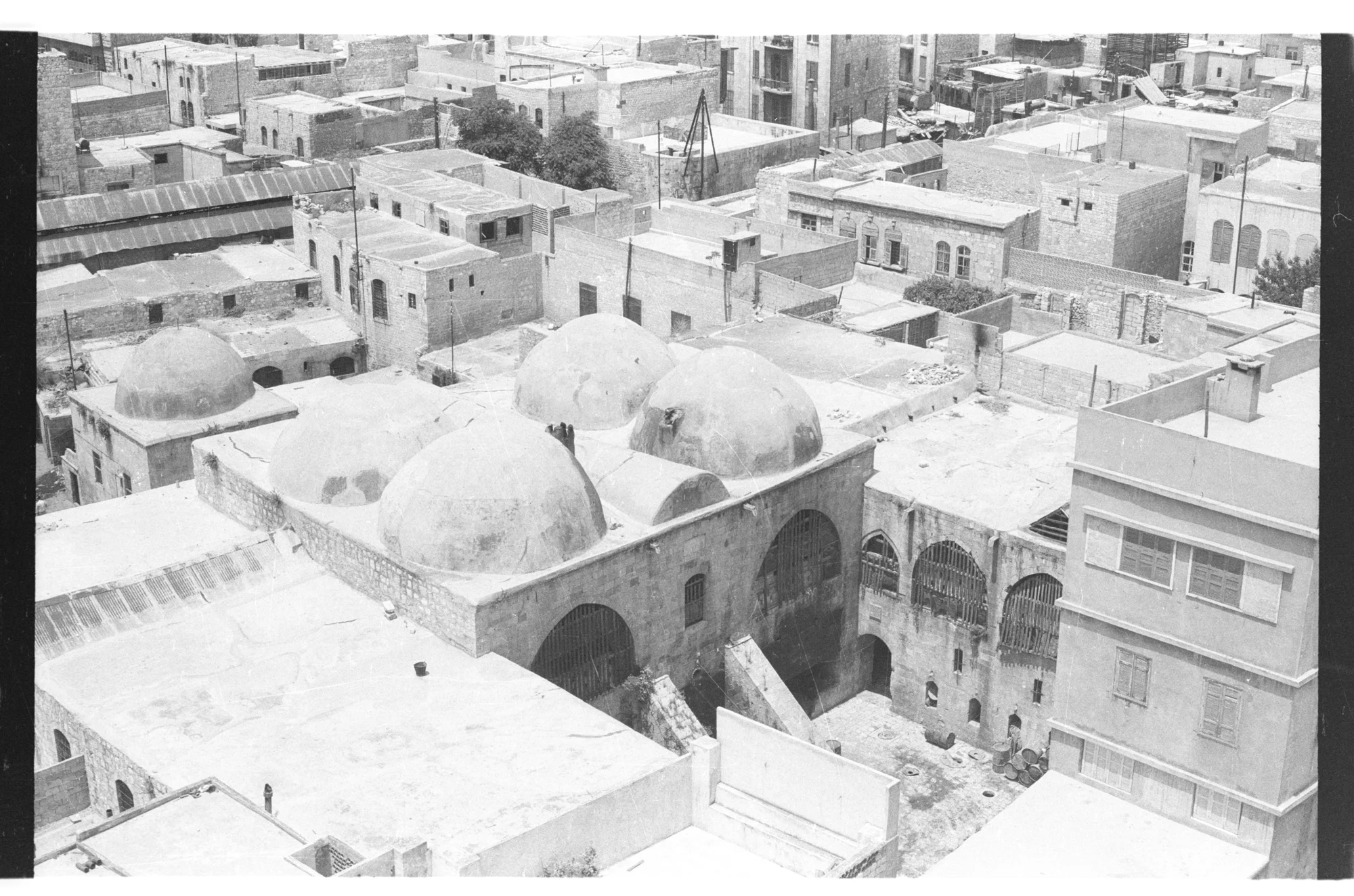

The soap factories require specific architectural features according to the phases of the manufacturing process. The entrances are similar to those of the bazaar, often having barrel vaults, rarely cross vaults. The entrance leads into a rectangular courtyard, where raw materials, such as laurel and alkaline materials obtained from the charring of the anabasis plant, are stored. These storage rooms are characterized by their small size and a barrel vault.

The heating room is located in the basement, which is accessible via a staircase in the courtyard.

The production of soap requires large areas. Therefore, these buildings have a large courtyard with symmetrical porticoes covered with cross vaults. Here, huge soap pots are filled with the liquid mixture of this famous soap.

Most work processes take place on the ground floor. The upper floor is dedicated to a single but essential task: drying the soap. The architecture of the upper floor is, therefore, of particular importance. It is designed to ensure optimal ventilation. The hall consists of parallel rows of arcades. Every square meter on this floor has its own function. The space between the arcades is an ideal place for pouring the soft soap liquid and for manual cutting at the end of the drying process. Between the arches, the cubic soap pieces are arranged in the form of carefully arranged towers so that air can reach all sides of the soap. The roof has many openings to allow perfect ventilation. This place smells of laurels for six to nine months, the time it takes to dry the soap before packaging, sale and transport.

Iraq sponsored one of the most important markets for the distribution of Aleppine soap. The war there, however, had a considerable impact on exports and led to their decline. However, the export of Aleppo soap to the European market has led to its revival. Although the recent conflict in Syria has destroyed and damaged some of the traditional soap factories in Old Aleppo, the remaining ones did not cease production and continue to employ traditional production methods.

In spite of all the adversities that have affected Aleppo’s famous soap industry, Aleppians have never stopped producing laurel soap. This traditional fabrication not only serves as a source of income, but also maintains a cultural heritage, distinguished as one of the most significant commercial centres in the Middle East.

Very Informative research. I need an original manufacturer contact in Syria, if available please.

Can i import Syrian soap to Thailand?

Thank you for your interest. Unfortunately, we do not have such business information, through we are aware of similar activities taking place within Syria!